Eco-HK

250–330 kW

A class of its own

Hot anniversary campaign - save now!

- Newest combustion technology

- Unique step grate system

- Automatic fuel quality detection

- Cost-reducing with eco mode

- In Cascade up to 2 MW

State-of-the-art wood chip heating technology

Heating boiler for the large power range

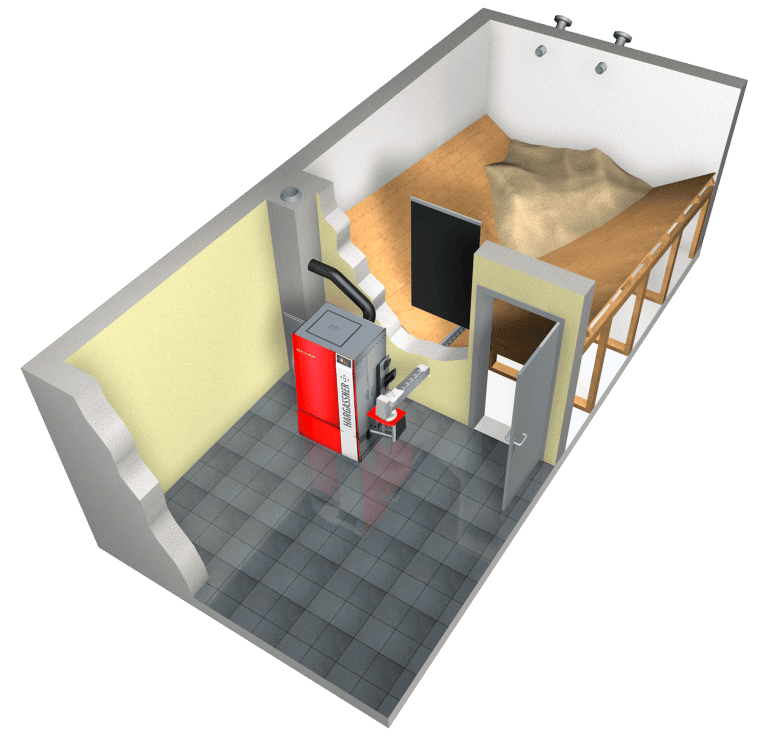

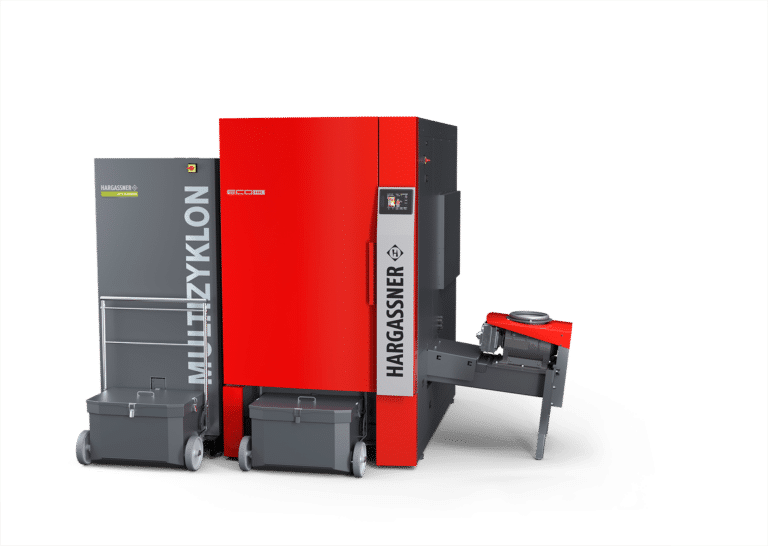

The Eco-PK 230–330 kW wood chip boiler is the most powerful in its class. The boiler is designed for the large output range and is ideally suited for use in commercial/industrial operations, apartment buildings, public buildings, industrial and local heating networks and many other areas.

The sophisticated and proven cutting-edge technology enables energy-saving, cost-cutting as well as fully automatic heating.

Benefits:

Eco-HK 250–330 kW

- Unique step grate system 3 revolving grates and 1 fixed grate

- Highest efficiency

- Firebed monitoring with contactless sensors

- Lambda sensor with fuel quality detection

- Heat exchanger cleaning system (in 1st + 2nd pass)

- Energy-saving ignition: 2 x 300 W

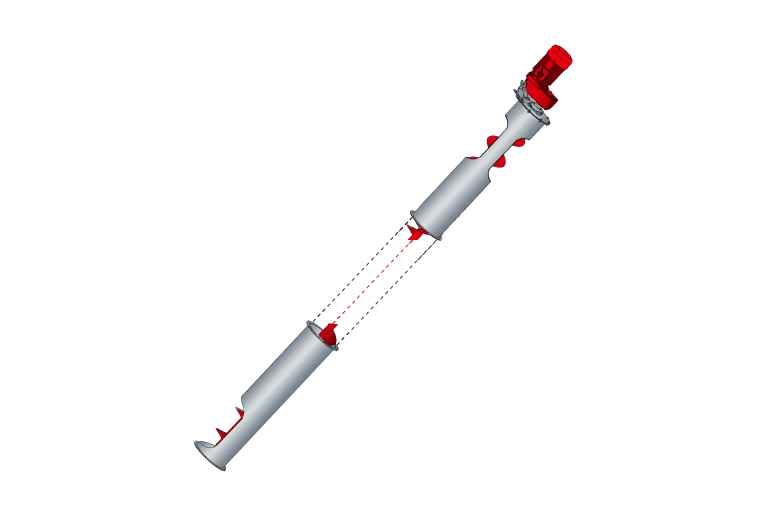

- Z-form double rotary valve - 100% burn-back safety

- Induced draught (EC motor) with vacuum monitoring

- Recirculation integrated as standard

- Combustion chamber sensor & tertiary air actuator - combustion optimisation

- Ash discharge for fly ash & grate ash

- No thermal safety circuit necessary

- Left & right boiler version (return lift always on the insertion side)

- Modern touch display control

- Mobile control - smart home app

- 5 year warranty acc. warranty card

- No loss of performance during ash removal

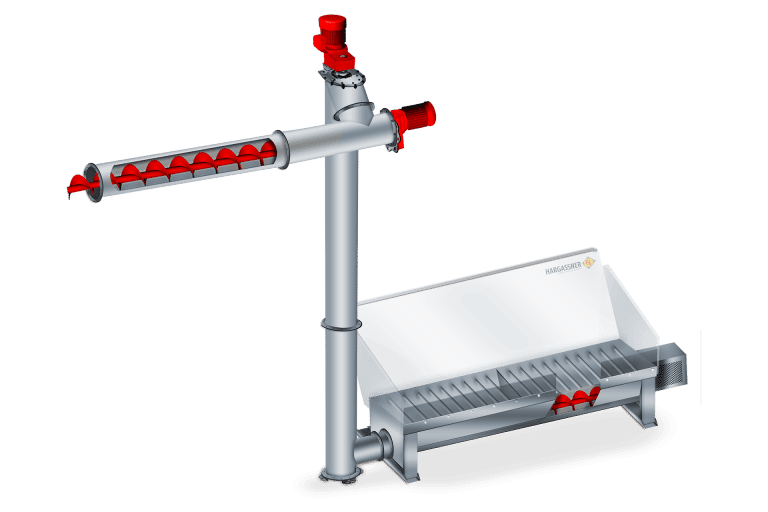

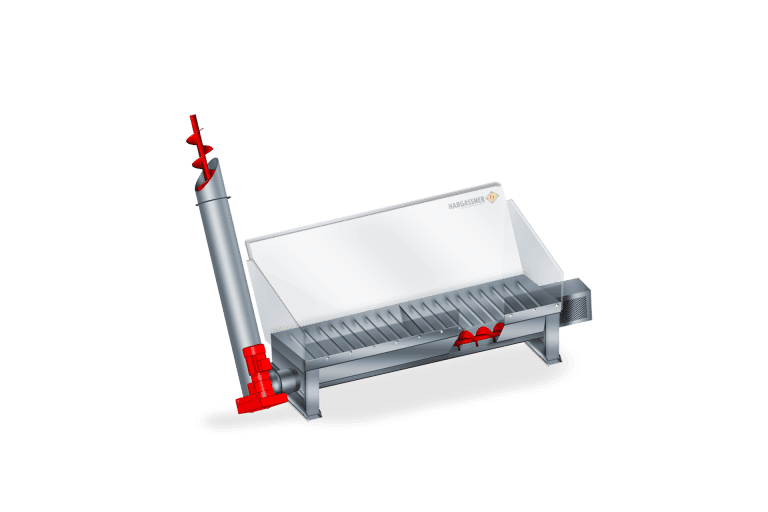

- Integrated return lift (optional)

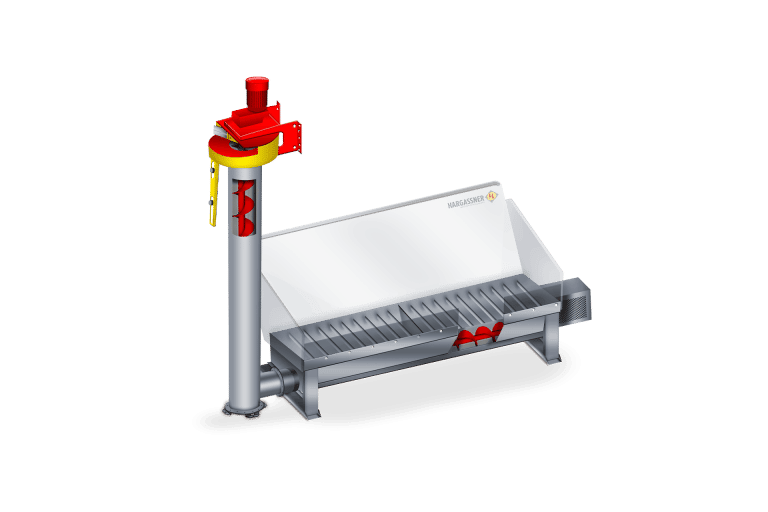

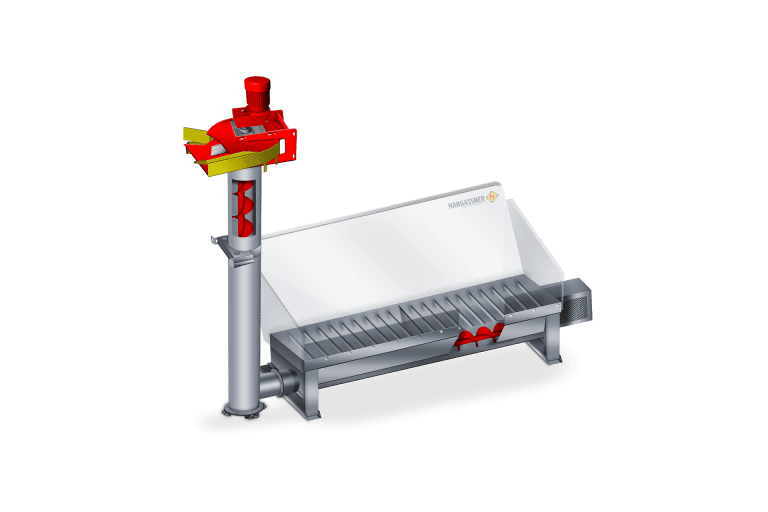

- Fully automatic ash extraction system (optional)

- Cascade controller up to 6 boilers - 2 MW

Our boilers in detail

Specifics

of Eco-HK 250–330 kW

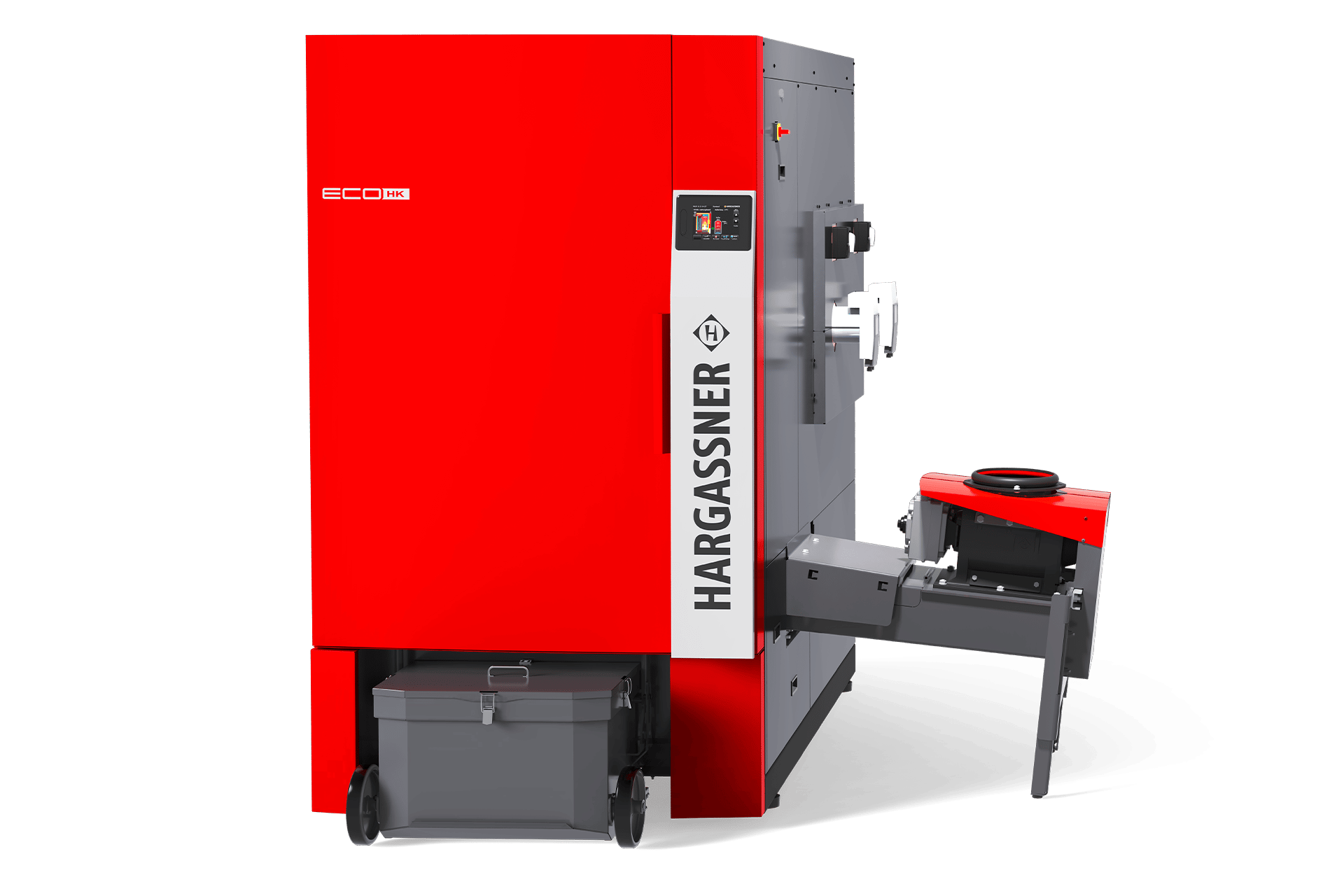

HIGHEST HEATING POWER IN PROFESSIONAL 3D!

Here you can discover the most powerful performance for trade and industry. Simply rotate, tilt or zoom the Eco-HK 250–330 kW boiler in all directions as desired.

For professional decisions, use the 3D visualisation to discover the latest wood chip technology right now and in your boiler room. Use augmented reality to visualise the future heating system by placing, rotating or scaling the boiler on your mobile phone or tablet using the AR button. You will receive a scale-correct representation of how the Eco-HK 250–330 kW integrates into your planning.

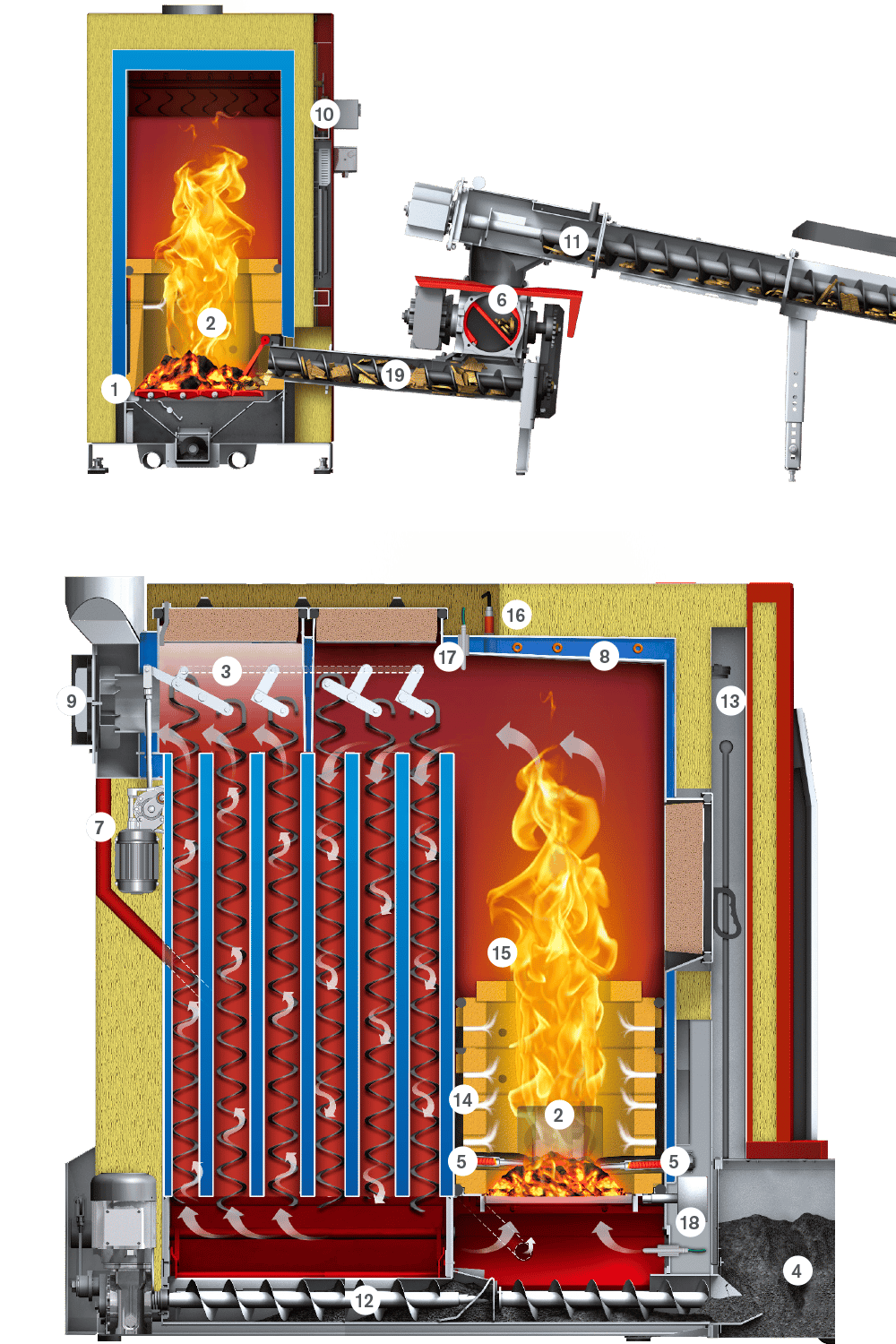

All technical details and important components are included in the following sectional view.

- Step grate system

- Firebed level control

- Turbulators with autom. boiler cleaning system (also in 1st pass)

- Ash box 75 l; optional: ash suction system for very long maintenance intervals

- Automatic ignition with 300 W x2

- Bicameral rotary valve in Z-form (22 cm depth)

- Recirculation

- Heat exchanger

- Exhaust fan (EC motor) with negative pressure monitoring

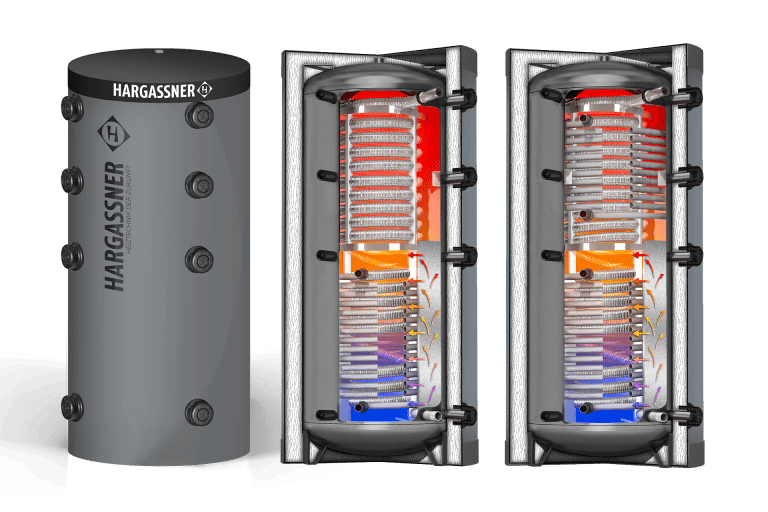

- Integrated back-end protection, optional

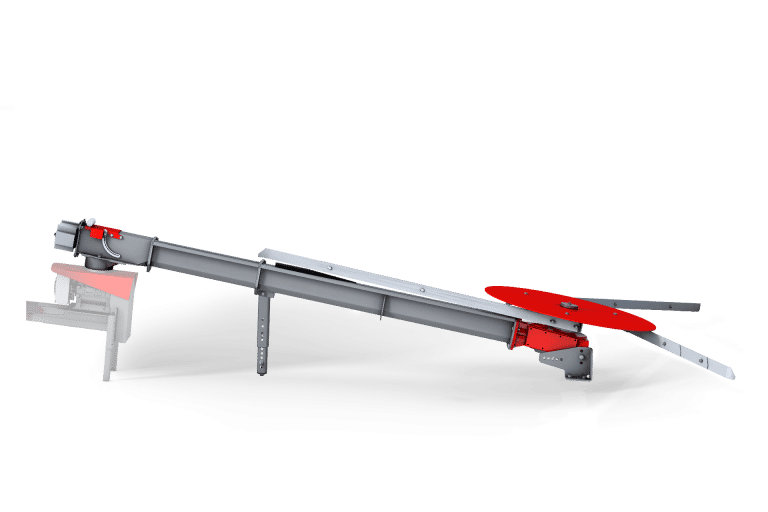

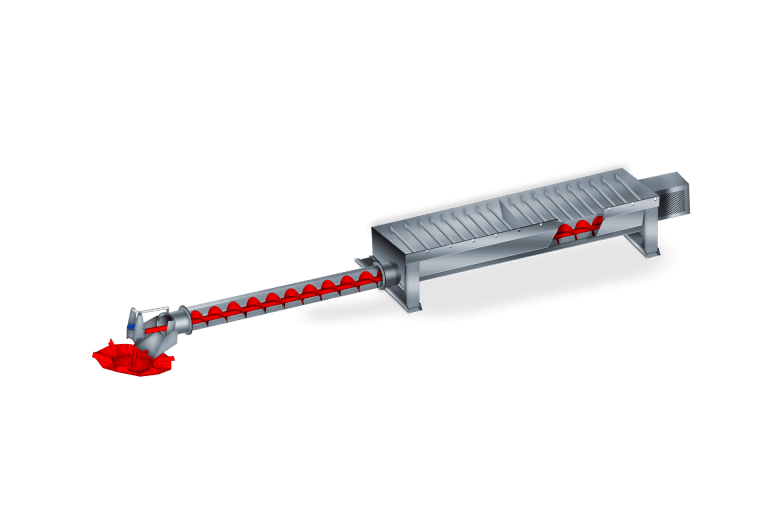

- Eco-RA – energy-saving fuel extraction

- Ash extraction system for fly and grate ash

- Negative pressure monitoring

- Fully refractory-lined combustion chamber

- Flame concentration jets made of high-quality refractory

- Lambda sensor

- Flame temperature monitor

- Grate temperature monitor

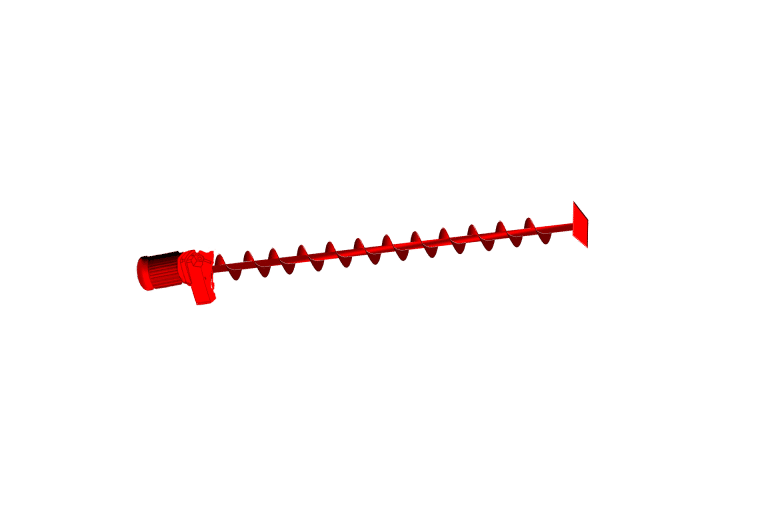

- Stainless steel stoker auger and pipe

A small insight

Target group

& possible areas of application

01

Contact us

Contact us for get some more

information and make an appointment!

02

Request

Our team looks forward to

hearing from you and providing

you with professional advice.

03

Appointment

We will inform you in detail

about our heating systems and the

corresponding heating supplies

for your biomass heating system.

04

Offer

We create an energy- and

cost-efficient offer that

is tailored to your needs.

You are a Hargassner expert, installer or dealer and need even more technical documents on our products and heating solutions? Use our partner portal, where you can also view an overview of your installed Hargassner heating systems. Simply log in and view exclusive information. You do not have a log in yet? Register now at partner login.