Hargassner Storage Systems

The best solution for every customer scenario

One of the most important aspects of installing a wood chip heating system is planning the fuel storage room. Regardless of whether the storage room is in the house being heated or in an adjacent building and regardless of whether it’s in the basement, at ground level or on the first floor, Hargassner has the right solution for every customer requirement. Of course, the storage room should be easy to fill and as big as possible or, as the case may be, as big as necessary. Installing the heating system in an adjacent building can offer some major advantages, because there is more space available and the storage room is also usually easier to fill.

Boiler room & storage room

at ground level

In an adjacent building or a boiler house: This type of storage room is filled by the chipper itself or by a tractor with a front loader.

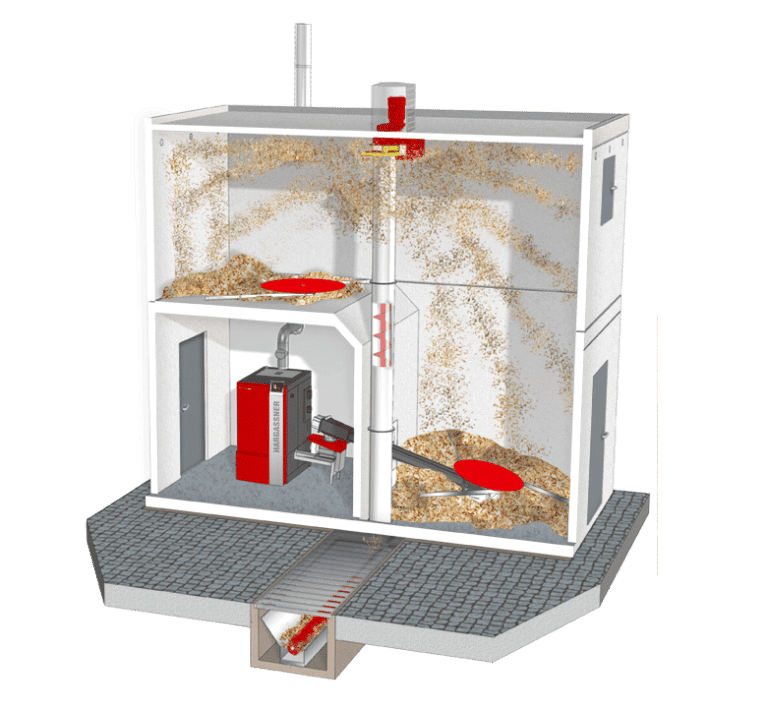

Boiler room & storage room

in an adjacent building

Here, the storage room (on the first floor) is filled by a vertical filling auger. The extraction is performed by an agitator system with downpipe.

Boiler room and storage room

in the basement

Here, the storage room in the basement of the house is filled by a horizontal filling auger on the ceiling with an outside shaft.

Heating system for a local

heating network

Here, the boiler and storage rooms are housed in a completely separate building. The storage room is below ground level and can easily be filled from the top.

Heating Modules

Storage Room Solutions

Are you looking for an alternative storage space solution? Take a look at our individually adaptable heating modules, which represent the perfect combination of heating & storage room.

Fuel extraction with coordinated concept

The storage room is on the 1st floor and the heating system at ground level? No problem! Hargassner offers a modular downpipe system for these situations. A downpipe is installed between the fuel extraction system and the stoker auger. This system consists of a basic module and different extension pipes of 100, 500 and 1,000 mm in length. There is an extendable pipe that can be adjusted to anywhere between 30 and 400 mm and enables the downward section to be set to the required length exactly. If there is a lateral misalignment, two 30° bends will be used. The fixation is made by clamping rings.

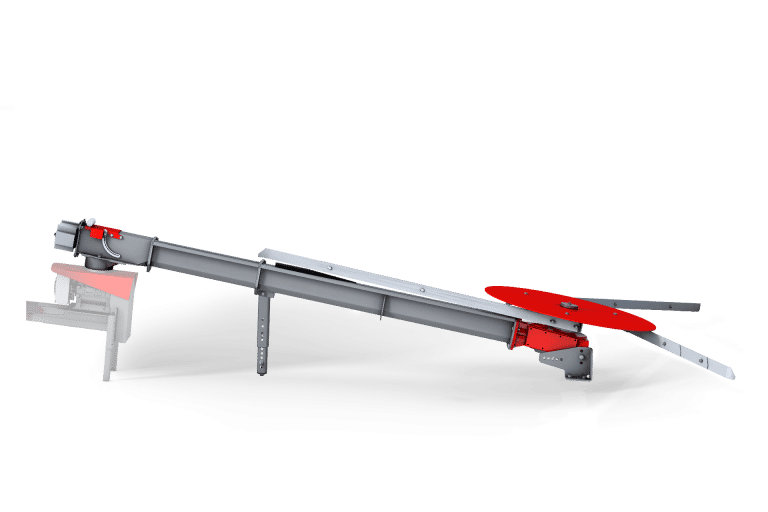

If there is a walkable space or aisle between the fuel extraction system and the stoker auger, the fuel extraction auger is countersunk and the connection to the stoker auger is made with the ascending auger. It consists of a drive unit and a 1 m basic module, and a range of extensions can be added to it.

If no direct connection is possible between the fuel extraction system and stoker auger, perhaps because they’re at different heights, there’s a gap between them or they are a long way from each other, for example, a connection auger is used. It consists of a drive unit and a 1 m basic module, and a range of extensions can be added to it.

If the storage room is one floor below the heating system, then a modular vertical connection auger can be used. A vertical auger is connected between the fuel extraction system and the stoker auger. This system consists of a basic module and different extension pipes. An extendable pipe, which can be adjusted to anywhere between 30 and 400 mm, and a 500 mm extension is integrated, so that the downward section can be set to the required length exactly. For a lateral offset, the mounting flange is infinitely variable.

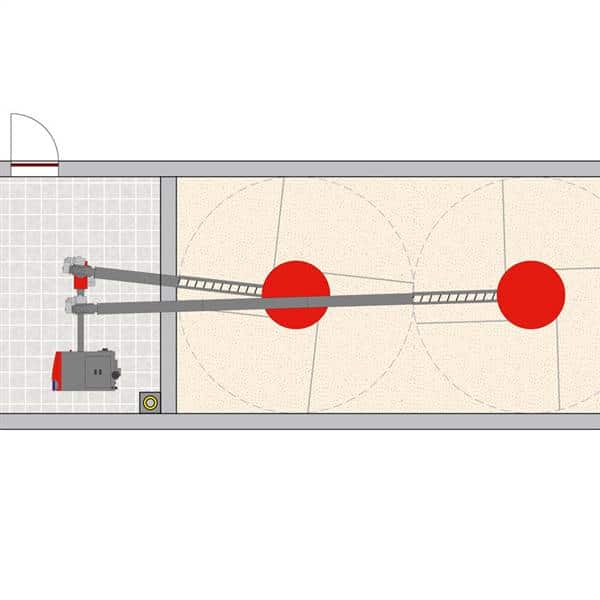

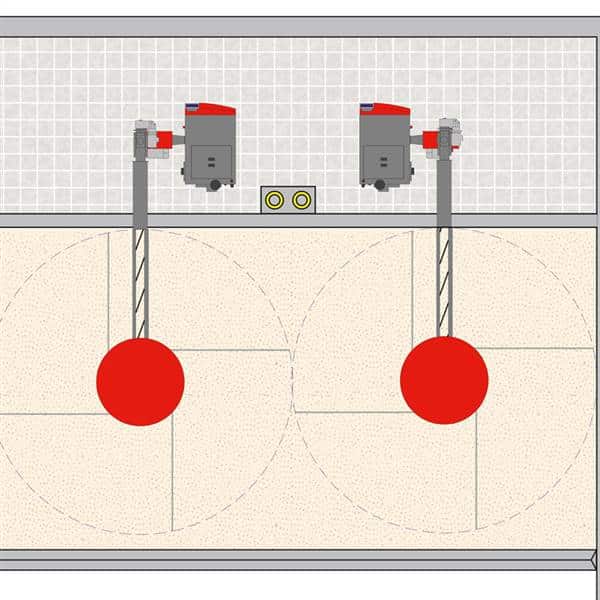

Second fuel extraction system for one boiler

This boiler concept offers optimum storage space utilisation in rectangular rooms. It increases the storage volume and the coverage. The boiler switches between the two fuel extraction systems automatically.

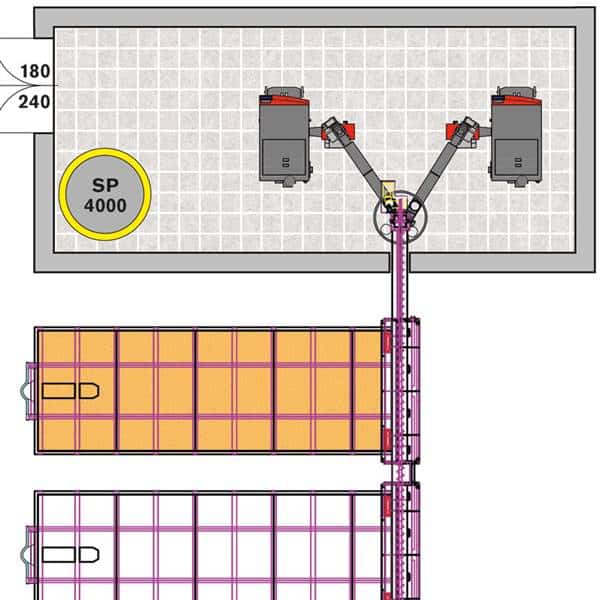

Cascade control for multiple boiler systems

This system concept offers significant advantages, especially in the medium and larger boiler system sector. Due to the special and exact operating mode of up to six boilers, the total power requirement can be optimally adapted to the season. Operational reliability is increased and the fuel storage capacity doubled while also guaranteeing you, the customer, optimum value for money.

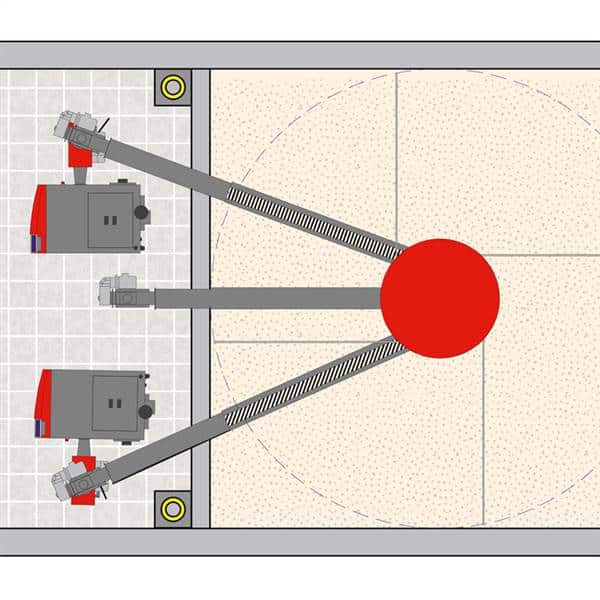

Two boilers with one agiator

The agitator comes with a closed auger duct and is powered by a separate motor. 2 separated connection augers with open shaft supply the two boilers. Both boilers are controlled by the cascade controller An additional DRM board is required to control the agitator.

This box is used for two, three or four Hargassner boilers with either a Hargassner fuel extraction system or an external extraction system such as a silo system or a moving floor system. It consists of a round container with a drive unit, adjustable legs and up to four openings for fuel removal. They are supplemented with a connecting auger unit and different extensions. This box can be equipped with a cover frame.