Smart-PK

17–32 kW

Compact size & functionality!

Energy label: A+

Hot anniversary campaign - save now!

- Compact design

- Pellets day hopper 174 kg

- Easy filling with bags of pellets

- Possible to place onto 3 walls

- Best price-performance ratio

Low-temperature pellet boiler

Convincing technology for the small power range

The new Smart-PK impresses with its modern design, its compact size, its functionality. The manual filling enables a sensational price-performance ratio and individual control over the fuel filling.

The storage tank allows a continuous burning time of up to ten days.

The Smart-PK 17–32 pellet boiler is also available as a wood log pellet combi boiler.

Benefits:

Smart-PK 17–32 kW

- Small, compact design

- Installation up against 3 walls

- Low-temperature tube heat exchanger

- Lambda control with automatic calorific value detection

- Highest efficiency and lowest emissions

- Full refractory-lined combustion chamber

- Speed controlled "energy-saving" exhaust fan

- Automatic sliding grate and ash drawer with compacting system

- Automatic energy-saving ignition with just 300 W

- Manual boiler cleaning lever for cleaning the heat exchanger tubes

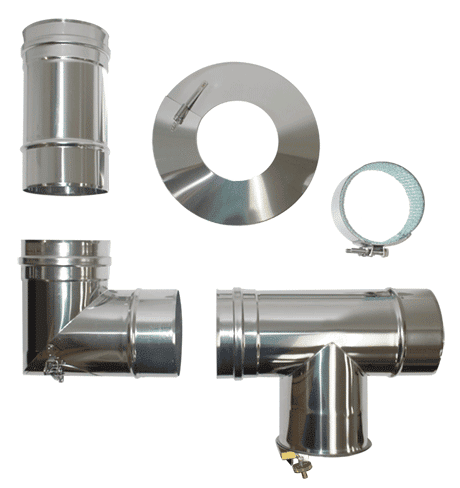

- Smoke outlet at the top, left side and back

- Pellet day hopper with cover, top grid and integrated fill level indicator (268 lt / 174 kg)

- Easy filling from bags of pellets

- Metering cell wheel for 100% burn-back protection

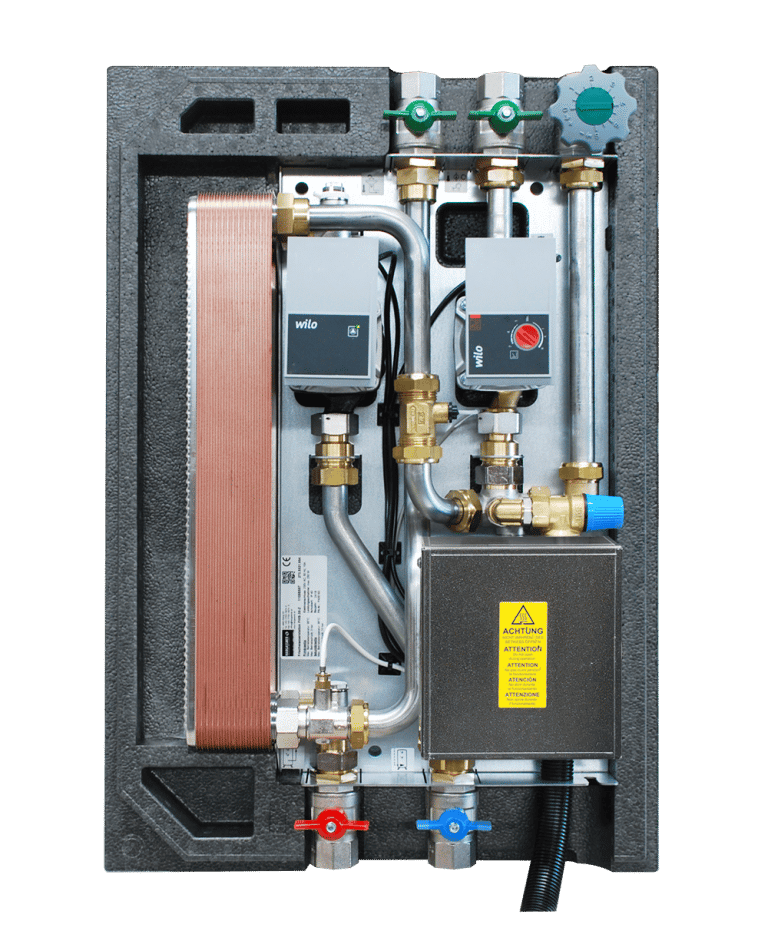

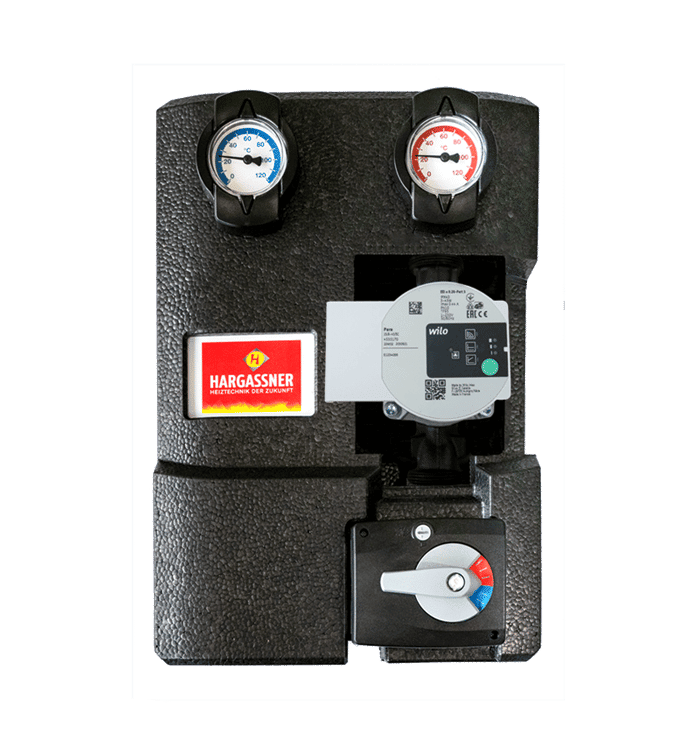

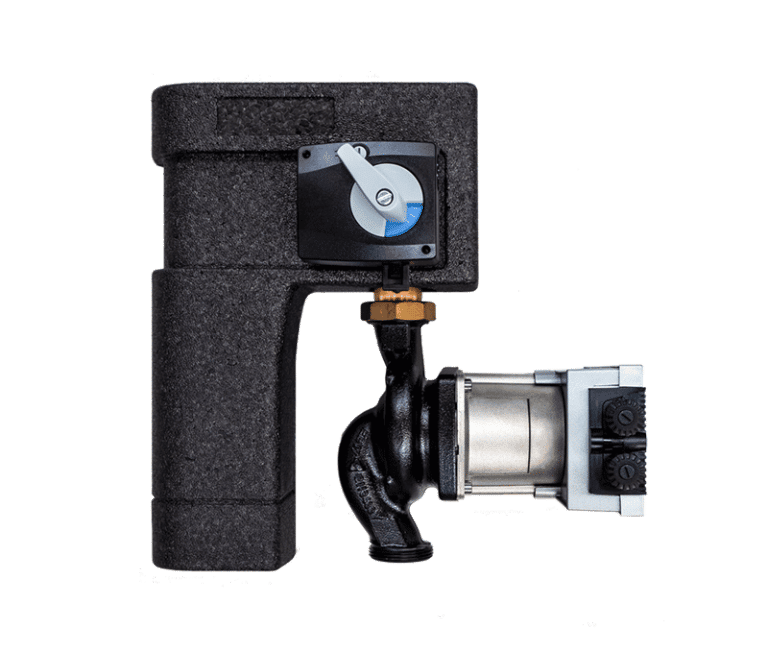

- Integrated hydraulic module available (option)

- Easy to use touch display

- Latest combustion controller for highest efficiency and lowest emissions

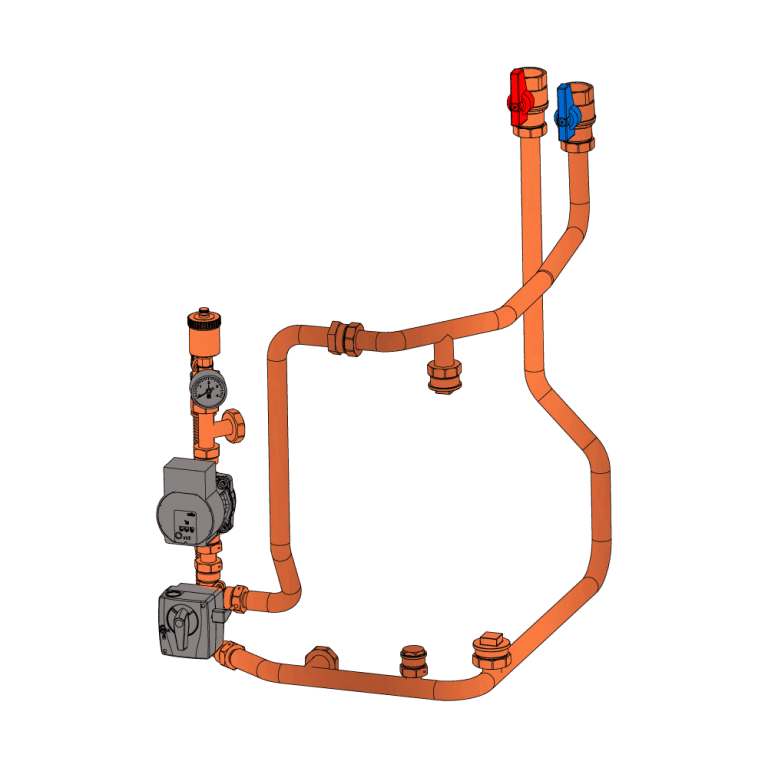

- Return & accumulator control

- 5 year warranty acc. warranty card

- Energy efficiency class A+

- Particle separator (optional)

- Integrated hydraulic module (optional)

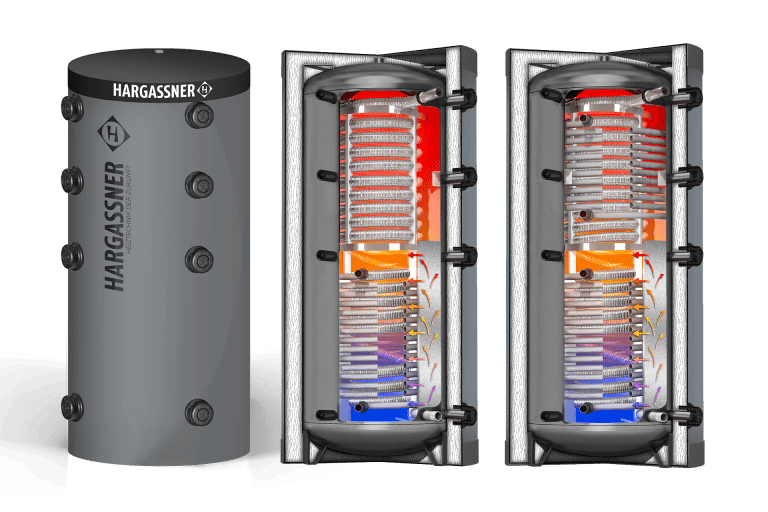

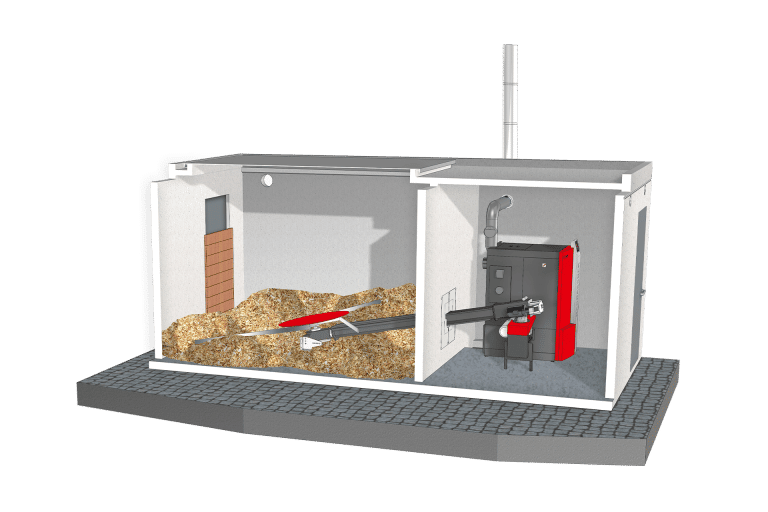

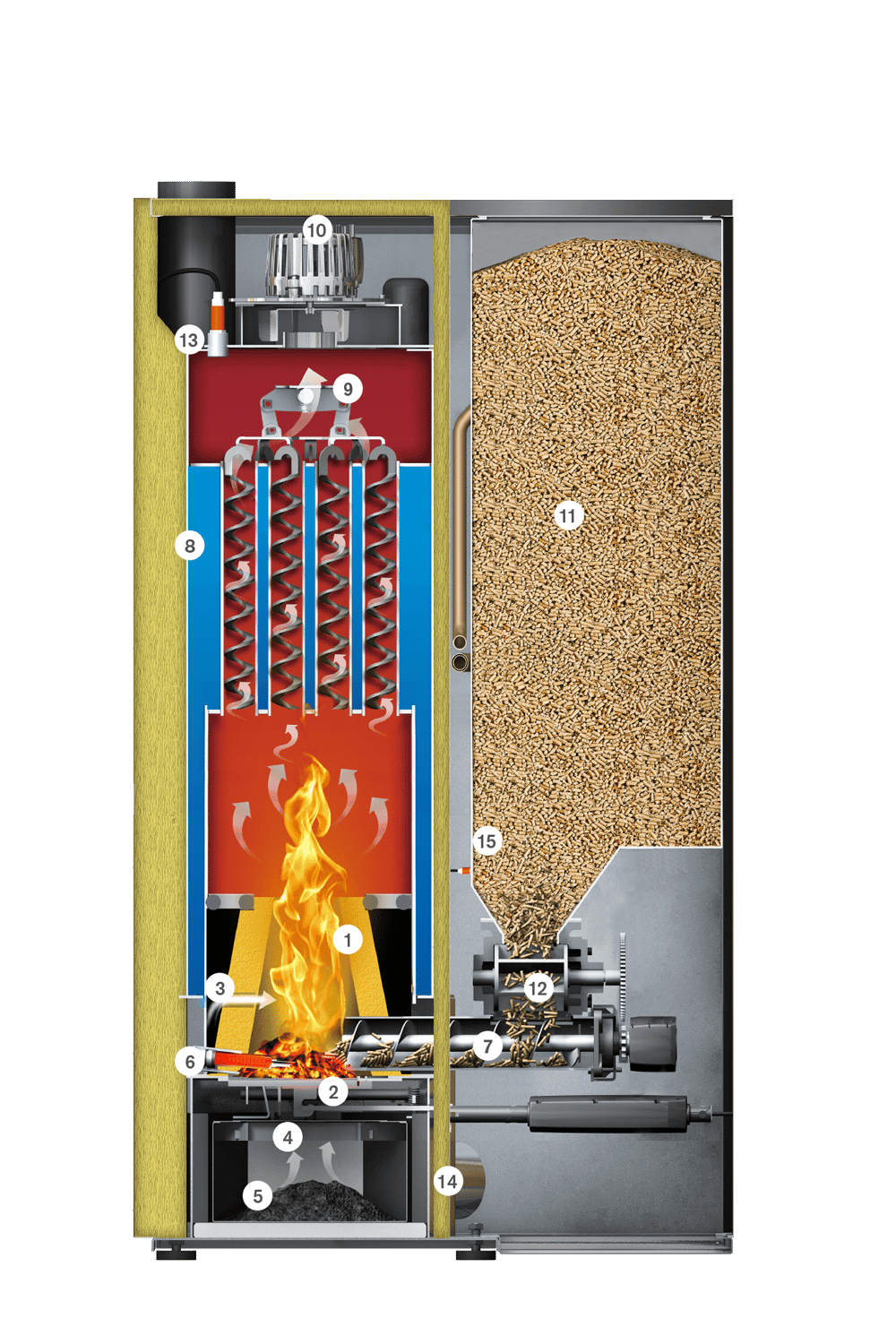

Our boilers in detail

Specifics

of Smart-PK 17–32 kW

Really SMART: our 3D visualisation!

Discover the compact pellet boiler with the sensational price-performance ratio from its best sides and in 3D here. Experience the Smart-PK 17–32 kW visually from all perspectives.

In addition, discover this cost-effective heating technology in your own future boiler room – right now on the screen. Augmented Reality makes it possible to place the biomass heating system in your future room. Simply click on the AR button and place, rotate and scale with your fingers.

Simply use your smartphone or tablet to place the boiler where you would like to see it later. You already have a foretaste of how the Smart-PK 17–32 kW can be perfectly integrated into your room.

You can find all the technical details and important components in the sectional view below.

- Fully refractory-lined combustion chamber

- Sliding grate

- Secondary air stream with inlet openings

- Primary air

- Ash pan

- Automatic ignition with 300 W

- Stoker auger

- Heat exchanger

- Turbulators with manual heat boiler cleaning system

- Exhaust fan

- Pellet day hopper

- Metering rotary valve

- Lambda sensor

- Air connection AIO / ADO

- Fill level indicator

A small insight

Target group

& possible areas of application

01

Contact us

Contact us for get some more

information and make an appointment!

02

Request

Our team looks forward to

hearing from you and providing

you with professional advice.

03

Appointment

We will inform you in detail

about our heating systems and the

corresponding heating supplies

for your biomass heating system.

04

Offer

We create an energy- and

cost-efficient offer that

is tailored to your needs.

You are a Hargassner expert, installer or dealer and need even more technical documents on our products and heating solutions? Use our partner portal, where you can also view an overview of your installed Hargassner heating systems. Simply log in and view exclusive information. You do not have a log in yet? Register now at partner login.