Extraction RAPS

Pellet Point Suction -

ideal for all room shapes

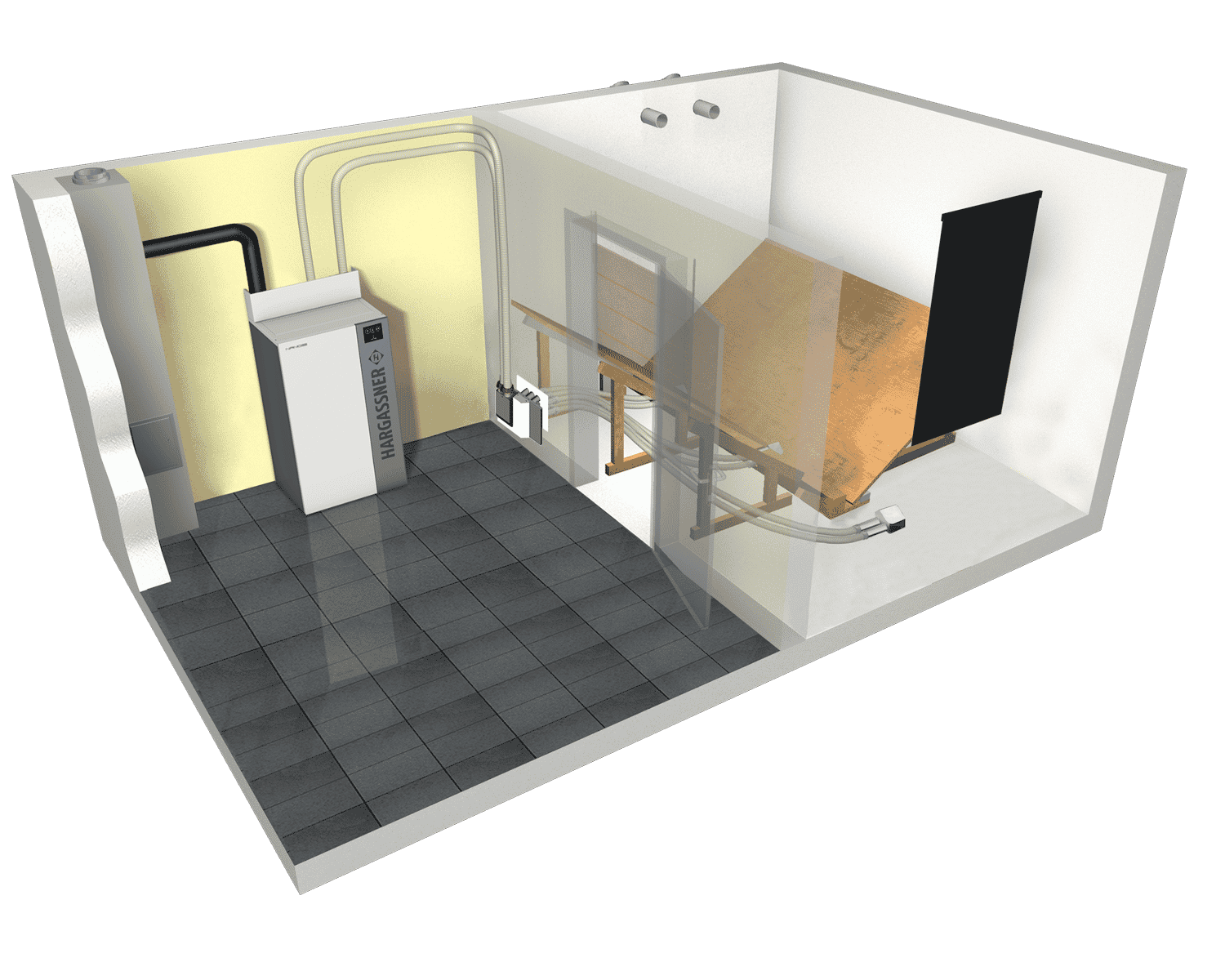

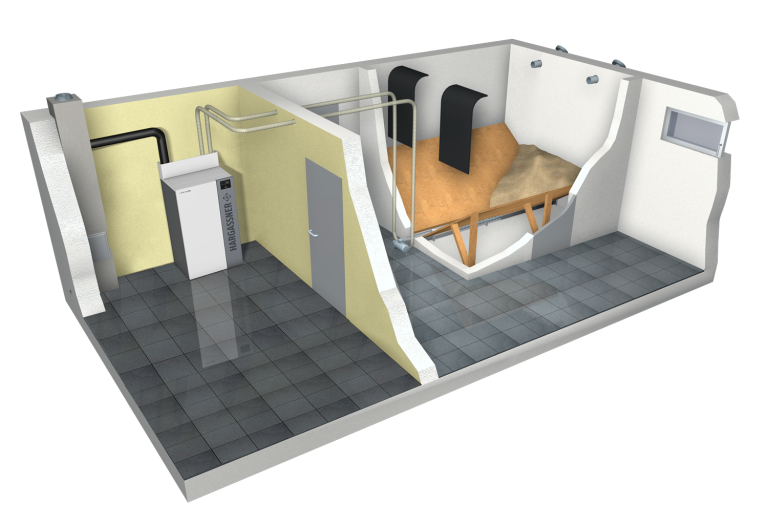

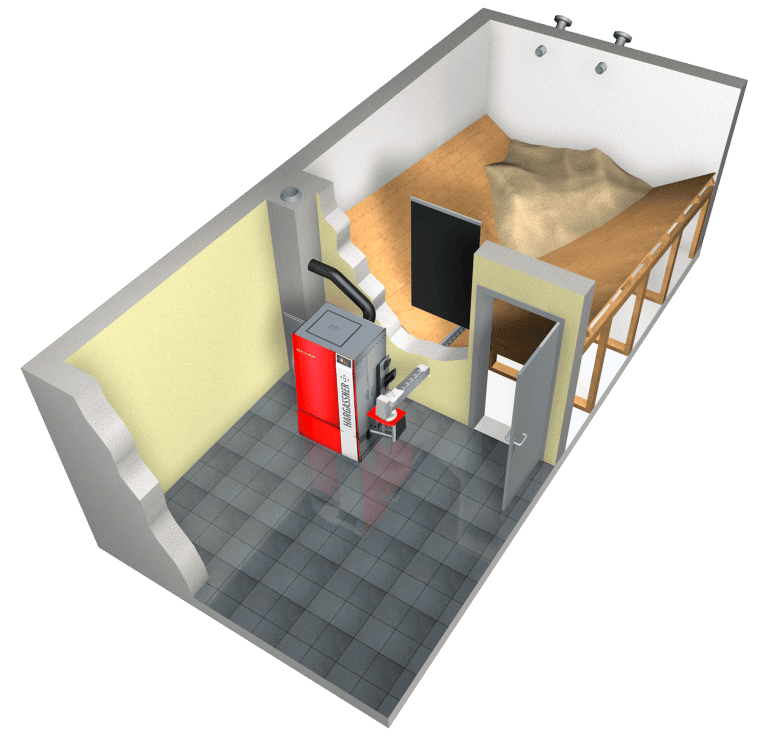

No matter whether small, square or complexly cut storage rooms, a point extraction system (RAPS) works everywhere.

One or more flexible extraction points suck the pellets out of the storage room. For this purpose, sloping floors made of wooden boards with a 35 degree slope are installed beforehand. They guarantee good emptying towards the extraction points. If an area of the storage room is empty, the system switches manually or automatically to another extraction point. The changeover units (AUP) are available in 2-, 3-, 4- or 8-fold versions.

They can even be used in small rooms without a sloping floor.

Point suction system

The point suction system is used for smaller and quadratic storage rooms. The RAPS point suction unit is placed in the middle of the storage room to empty the storage room in the best possible way.

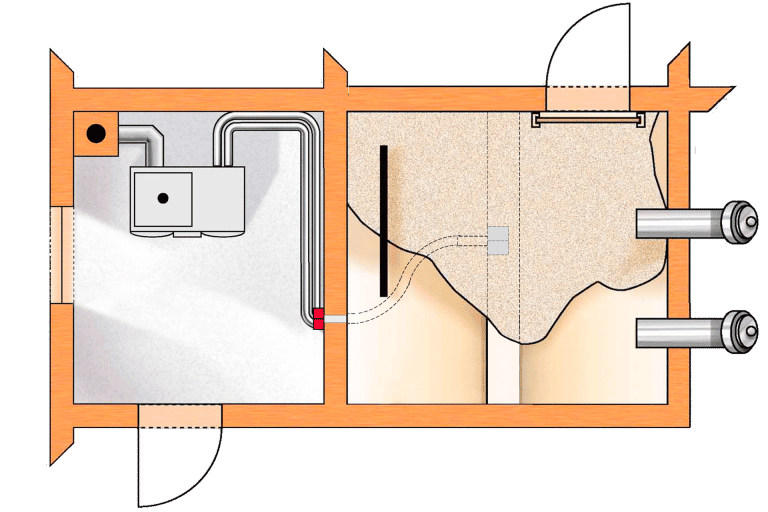

Point suction with automatic changeover unit AUP

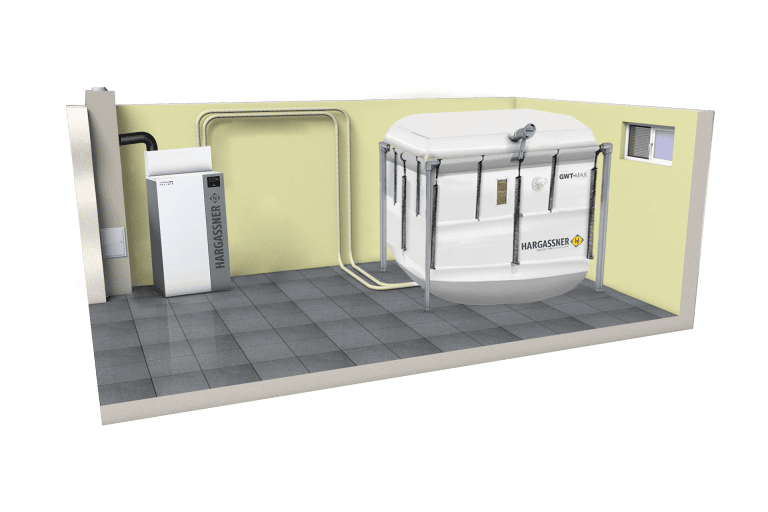

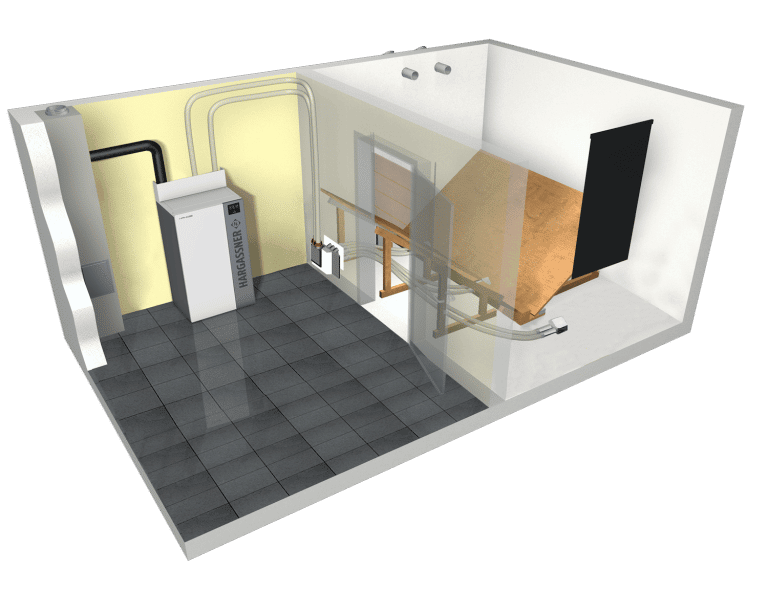

For larger rooms, more point suctions systems can be installed in combination with a manual or automatic

changeover unit.

- Up to 3 point suctions can be combined with the UE manual changeover box.

- With the AUP automatic changeover unit, you can place up to 8 points in the room. This is a perfect solution for large storage rooms with sloping floors or small storage rooms without sloping floors.

The advantage for the customer is optimal emptying of the storage room, regardless of whether it is a large or complex room situation.

Storage room preparation

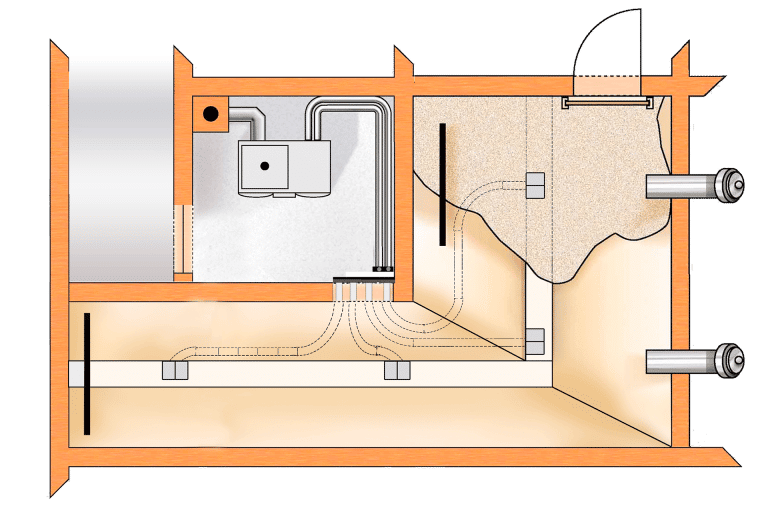

Depending on the size and shape of the room or the selection of the quantity of point suction units, the storage room must be structurally prepared accordingly.

- 35° sloping wooden floor

The storage room is provided with a 35° flat wooden floor on at least two sides. This guarantees trouble-free pellet transport and ensures good emptying of the storage room. - Storage room without sloping floor

With the use of multiple changeover units (AUP), you can even work in small rooms without a sloping floor.

Benefits of a

Point Suction

- Ideal for small to complex rooms

- Makes optimal use of the room volume

- Automatic changeover unit AUP

- Fully automatic switching of the point suction unit

- Saves time and costs

- Up to 8 points possible

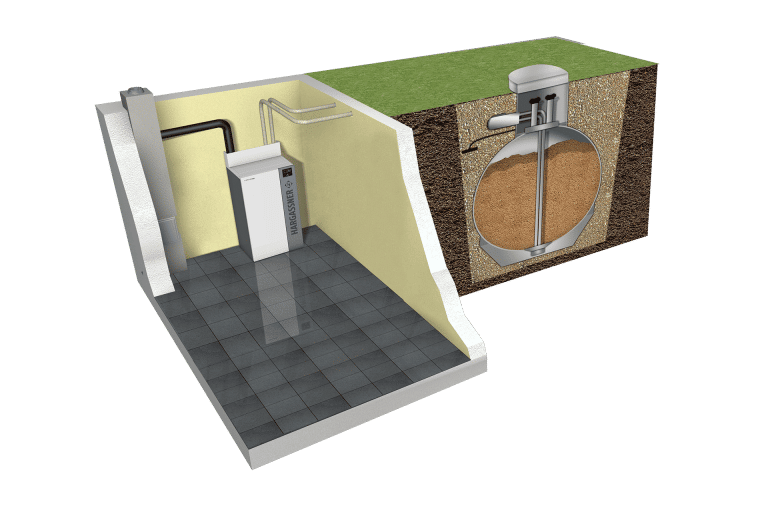

- Distances up to 20 m between storage & boiler room

- Up to 20 m distance between storage & boiler room

When using steel pipes instead of the suction hose up to 30 m - No sloping floor necessary in small storage rooms

Steel suction tube system

Expert Tip

If you decide on a pellet boiler with an output of 130 kW or more, we recommend installing a steel pipe system instead of the suction hose. With higher output and thus more demand on pellets, damage can occur due to friction when sucking on the hose. By using steel pipes, you can avoid this phenomenon and thus ensure trouble-free and repair-free suction of the pellets. Furthermore, this also increases the distance of the suction length between the storage room with point extraction system and the boiler room by 10 m to a maximum of 30 m.