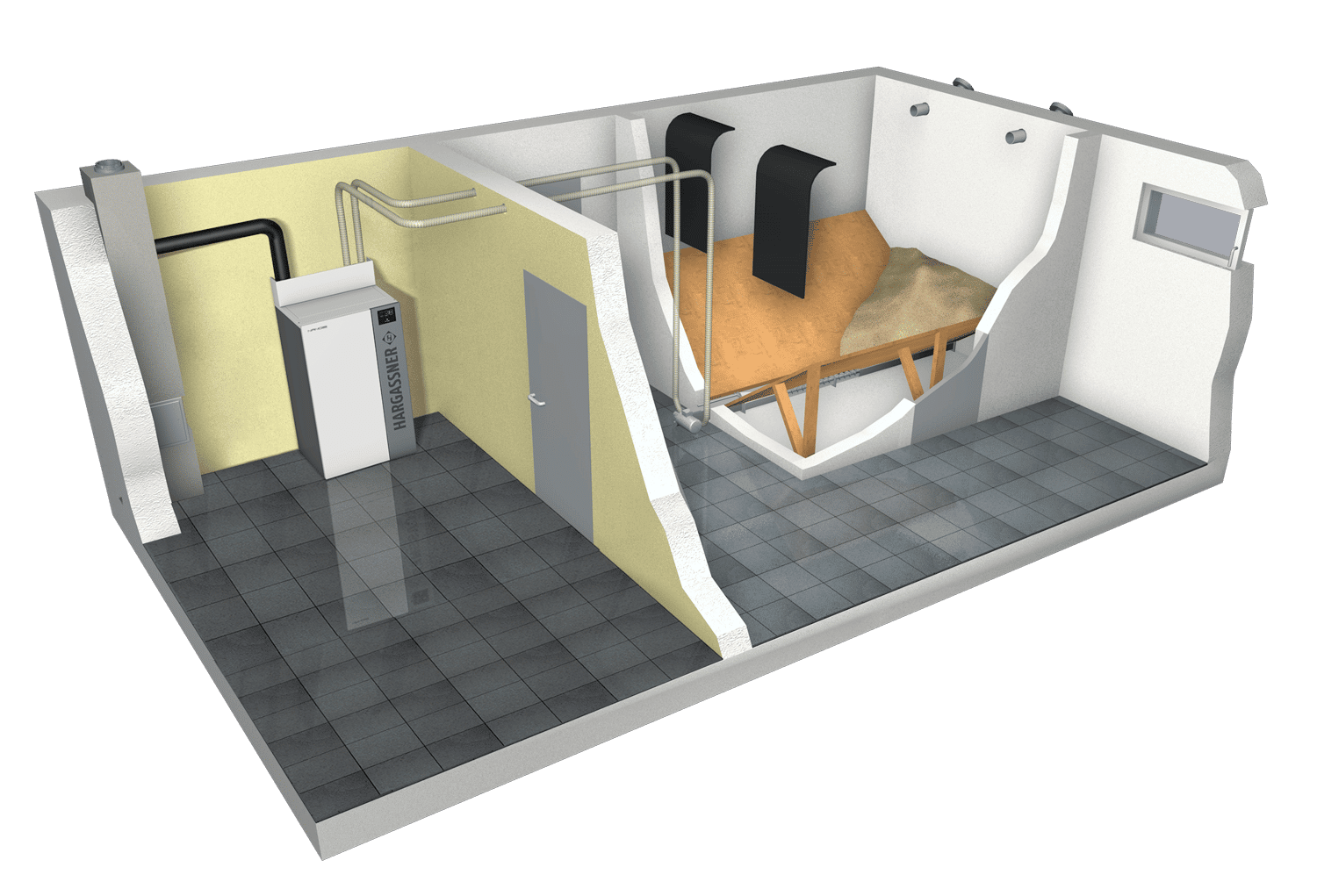

Fuel extraction auger

Reliable for any size

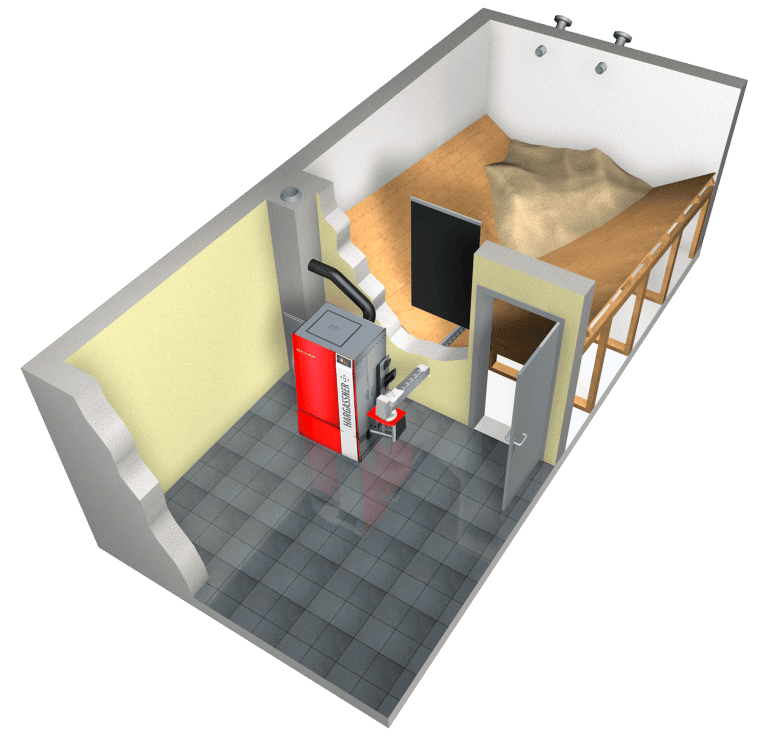

Thanks to the combination of suction system and extraction auger (RAS), every pellet finds its way safely to the boiler.

Fuel extraction augers show their robust strength in long storage rooms with space for an extraction motor. With the transport auger, the pellet quantity can be finely adjusted during transport. The suction system is completely emptied when it is switched off, thus avoiding overfilling jams. Sloping floors help with the optimal feed of pellets to the auger. It is even possible to combine two extraction augers, in which case an automatic changeover unit (AUP) is used to switch between them.

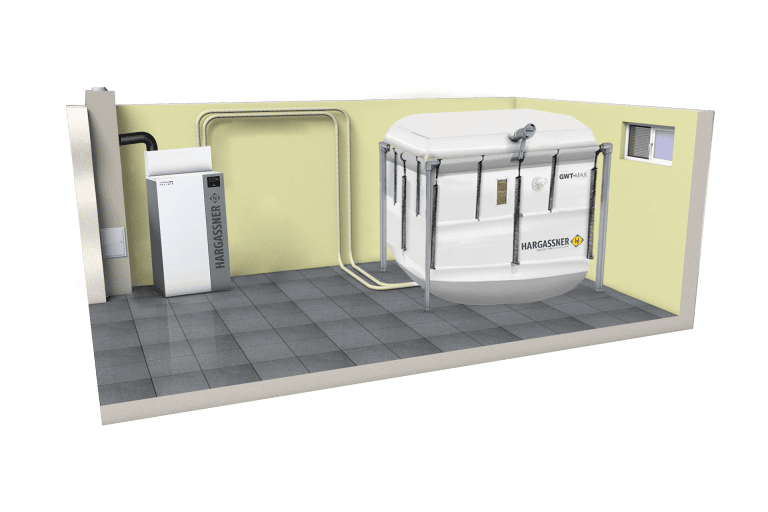

Extraction RAS

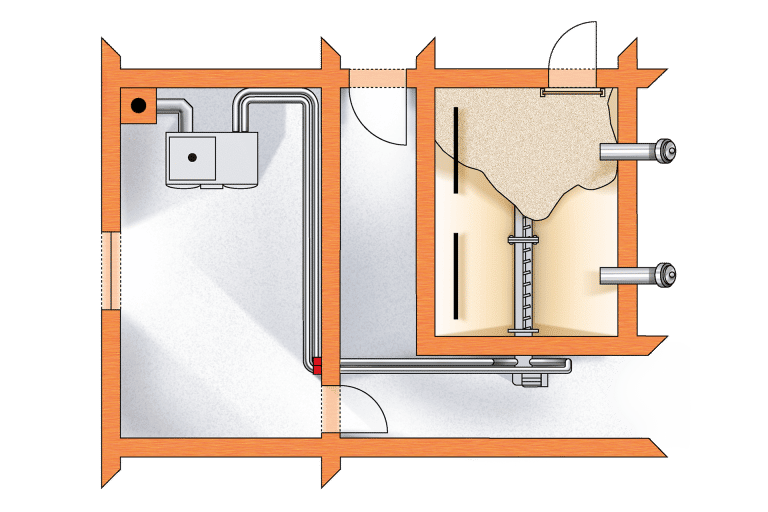

Auger suction extraction RAS

This auger-suction combination is used for larger and elongated storage rooms. Distances up to 30m between storage room and boiler room are no problem. Maximum operation safety through dosed pellet feeding system and low electrical power consumption through short suction periods. For extra-large storage rooms also a double-RAS system can be installed in combination with an automatic changeover unit.

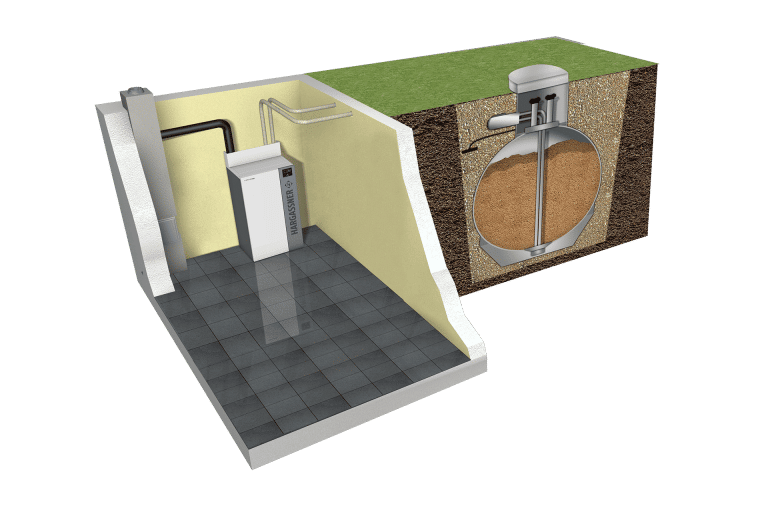

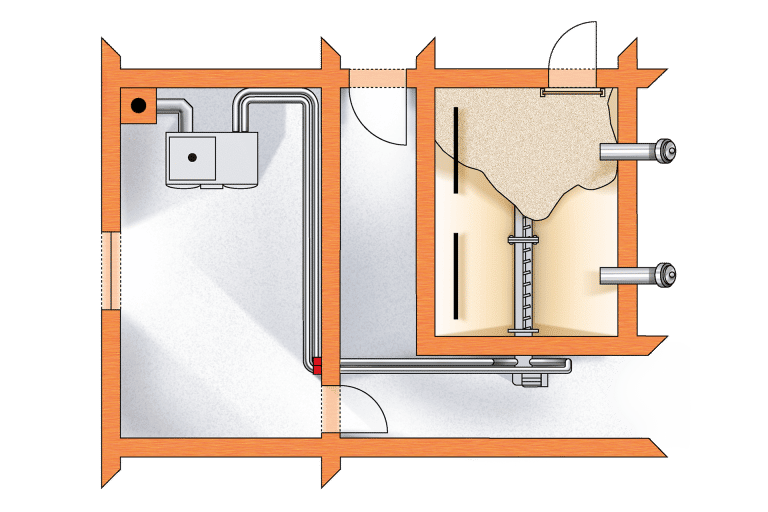

Extraction AUP

2 storage room extraction augers for one 2-point auto changeover unit

For large and square wood pellet storage rooms, 2 extraction augers are installed. The changeover from one to the other auger takes place through a 2-point auto changeover unit. The result is an optimum storage room extraction and an efficient way to use larger pellet volumes over longer distances.

Your Benefits

Benefits

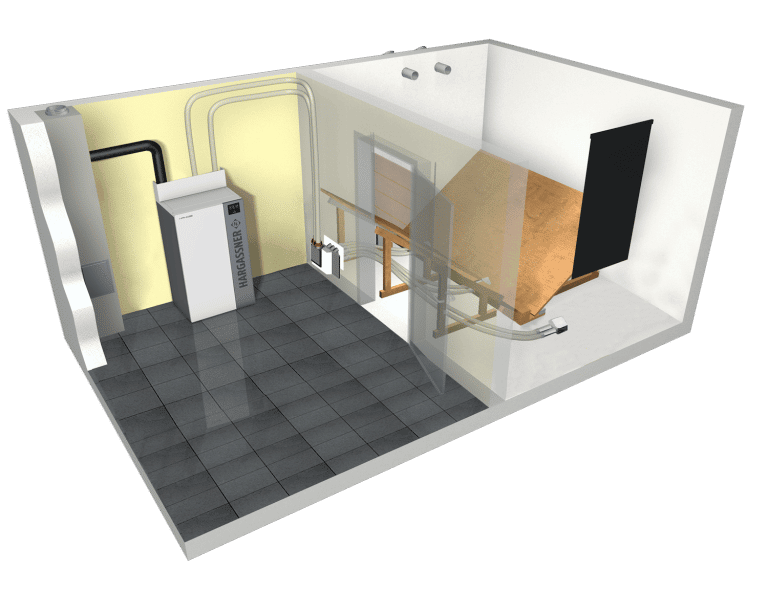

Extraction Auger

- Ideal for long rooms

- Distances up to 30 m

between storage & boiler room - Robust and reliable

- Two extraction augers Combine with AUP

- Optimal use of the room volume

- Auger lengths of 1.5 – 8 m

Steel suction tube system

Expert Tip

For pellet heating systems from 130 kW we advice to install steel pipe systems rather than a suction hose. The hose could be damaged under certain circumstances because of the high suction speed and force with which pellets are sucked through the hose. So with the decision to use steel pipes, this phenomenon can be avoided.